Refit diaries: 11/30/25- 12/7/25

Did you see our holiday gift guide? Check it out here!

Our family is in town visiting and luckily, we’ve come up with perfectly reasonable excuses to hit “pause” on anything that requires us to physically be at the boat: Installing the new forward hatches in the salon? There’s been way too much rain. Obviously we must wait for better weather so the sealant can cure properly. Wiring work? Totally impossible to continue until the new air conditioning units and Quattro arrive! Literally anything else? Will be easier once the workshop is complete! Instead, we walked the beautiful New Zealand beaches, explored the local market, and enjoyed some quality time together at our rental house, with great food (thanks to the Grill Master, my dad) and excellent wine. I’ve even convinced my mom to join the local pilates studio with me!

Sewing

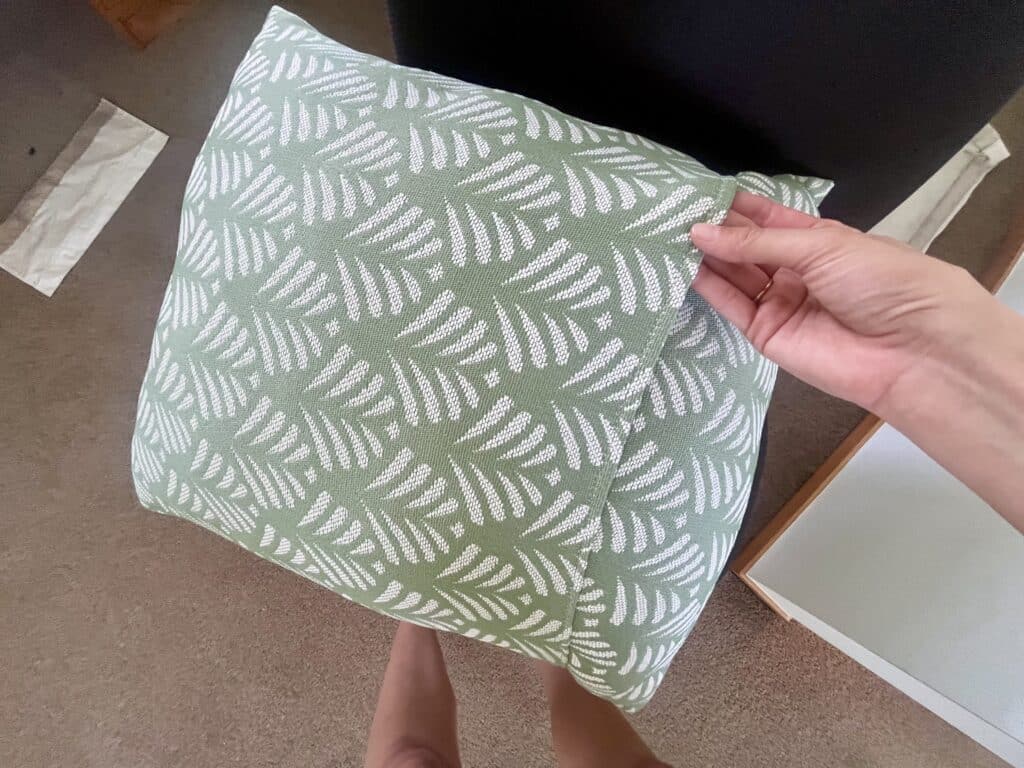

We haven’t halted all progress though, this week, my mom and I finished sewing the new line bag! The curved binding was challenging, and keeping the double layers of fabric aligned took patience, but the end result is strong and should serve us for years to come. We’re hoping to install it at the helm next week, so I’ll be sure to take some pictures! We also made an envelope-style throw pillow cover, which means no zippers to worry about rusting shut. I’m not totally convinced this design will hold its shape, so we’re going to live with it around the house for a bit. If it doesn’t get floppy, we’ll make another one.

We’ve started mapping out our first salon cushion. This is the project I’m most nervous about, because I know ill-fitting covers would bother me every single day. We took apart the original cover to use as a pattern and decided on a semi flat-felled seam. It leaves one row of stitching visible on the outside and two hidden underneath, which means excellent strength, minimal UV exposure to the thread, and better water resistance than an overlapping seam. These are indoor cushions, but we’re hard on our upholstery aboard Sabado. We’ve stripped off all the old batting from the cushion foam and are replacing it, but the foam itself is still in good shape.

Electrical

We try to keep our systems aligned with ABYC standards. With recent updates to the guidelines, Ray has been re-thinking parts of our electrical upgrade/rewire, like including adding a Class-T fuse on each battery to meet the AIC requirements. We’re also installing a Blue Sea remote solenoid, giving us a helm-mounted switch that can instantly cut power to the winches and windlass. After reading about this tragic accident, that extra layer of safety felt like an easy decision.

Mast parts update

Between the high cost of VMG Soromap replacement parts and the substantial investment required to switch to Harken, we’ve decided to make do with the system we already have. It’s an issue we’ll revisit in the future.

We also checked off a few general to-dos, like washing our foul-weather gear and organizing some of the Ray’s spare parts and components into new storage containers. Overall, it’s been a slow week of progress on the boat, but taking some time off is better for us in the long run — this refit is a marathon, not a sprint!

We hope you had a great week. 🙂

2 Responses

Definitely a tragic accident for the skipper going up the mast. As we prepared for the ARC crossing in 2021 they had a traning on going up the mast and they identified the issue of the winch not turning off due to a faulty relay. Their recommendation was that the self tailer should not be used when someone is going up the mast. If someone is manually tailing the halyard then it is easy to let it slip on the winch if the equipment malfunctions. This raises the issue when short handed on the Lagoon 42 – how to push the button while using 2 hands for tailing. Our solution was to wire a remote for the winch that works in parallel with the buttons. This way the person going up can control the winch and the other person has 2 hands free to focus on tailing.

Hi Ray…. This one I suppose is for you.

But first of all, bear with me, regarding both my english, and lack of knowledge of the insides of the mast.

But this was my thought, every time you have talked about the problem with ‘loose’ wires inside the mast .

And that you probably have thought of the following, – but since I can’t recall you do mention it, I decided to write you.

The lack of a hard conduit in one side….:

Is it not possible to somehow place a flexible kind of conduit, that could be fixed/secured, in a few spots, so that is fairly fixated, and would not be dangling much around?

You mention that you, or Hollys hands, can get inside in places, but not how many places..

I am thinking of the type used on land, in the ground or in buildings. Comes in many sizes.

Intuitively I think that these types, can not make as much noise as loose cables, when hitting the masts inside walls.

And the weight etc, might prevent them from dangling much, if anything, against the mast.

And even if it would do that, again I imagine the noise is very different and a lot less…

And I believe you could make access holes in it where needed. So cables like the ones starting at the spreaders could run in the same, as cables starting at the top.

I admit, I have no idea how difficult it would be to get one in place, so that might kill the idea.

But, as I said, you probably have thought of this solution already, and in that case, could you maybe say a few words about it, in one of the next videos…if explaining about it here is difficult…?

I am probably not the only who has been thinking of this solution.

And:

I believe you so VERY much, when you talked about the annoyance of it… It makes me think of when sailors have not fixed their halyards, when in the marina…

I think I heard that here in the EU they are considering making it a crime to do so…. Or maybe that was just wish full thinking!

Fair winds, and enjoy the work

Torsten Stjernholm